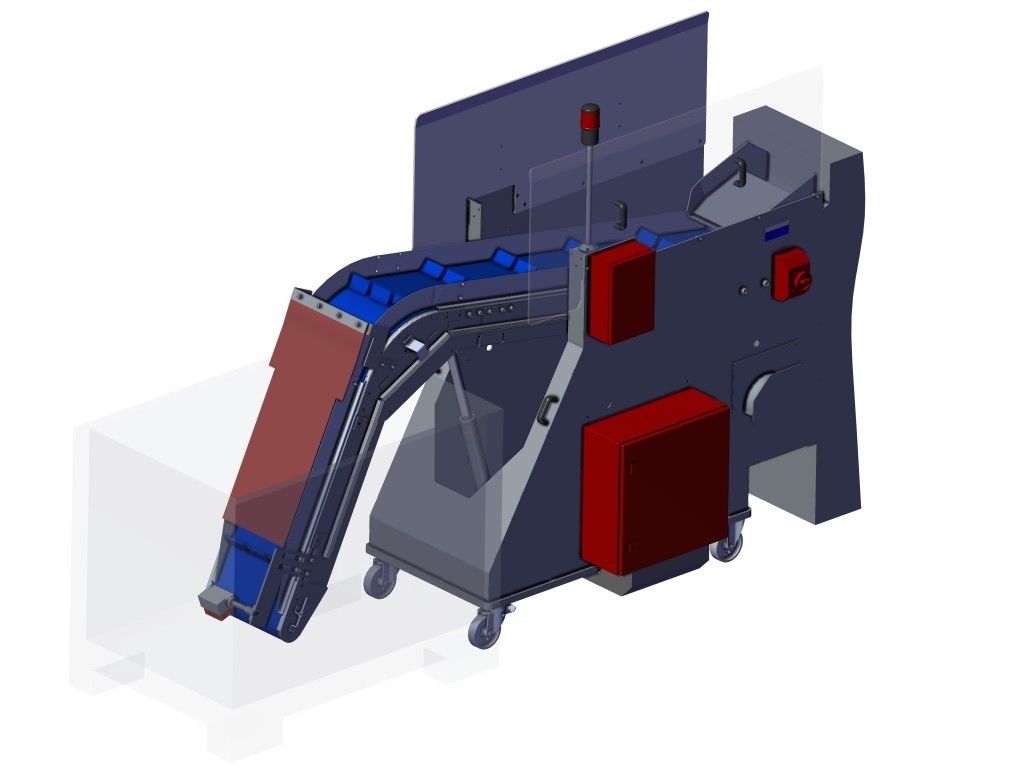

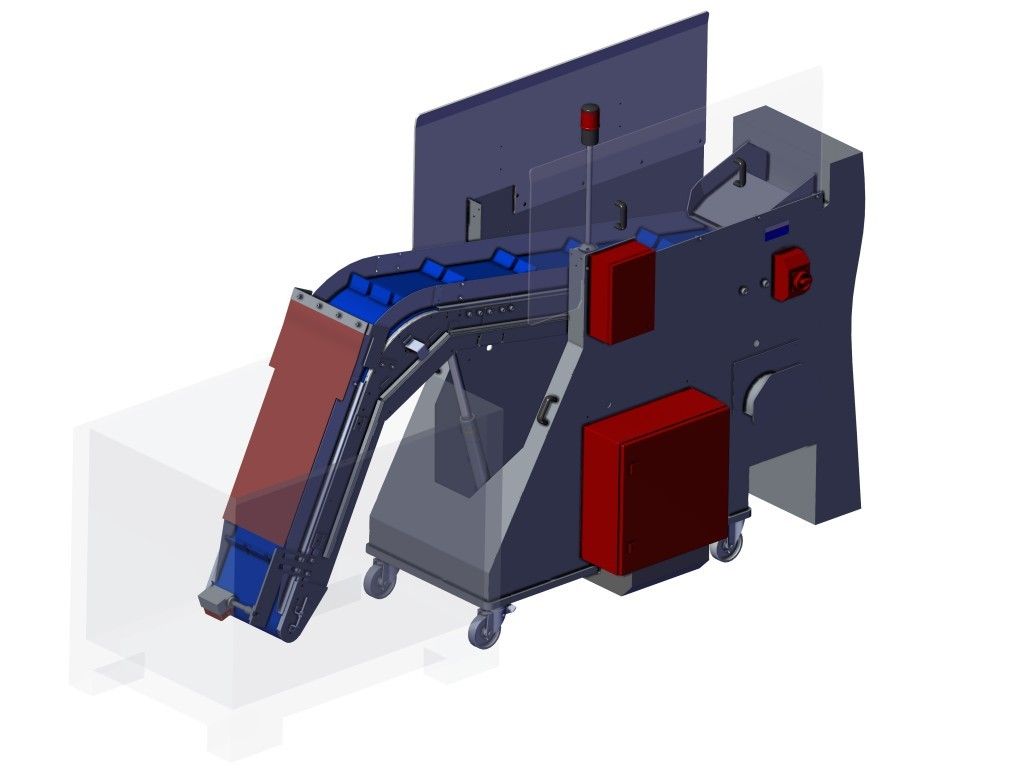

Machine: Magnet Belt Loader / Unloader

Magnet Belt Loader / Unloader

After machining, the belt loader transfers workpieces sensitive to damage with a minimum drop height into a bulk container. The sensor installed at the head end of the angled conveyor continuously monitors the level in the box to be filled and gives the integrated control the command regarding the correction of the discharge height. When the container is filled, the electric cylinder moves the belt conveyor into the top final position so that the box change can be carried out.

In the new, non-magnetic design, the workpieces are transported into the box by means of a studded belt. The descending gradients can be equipped optionally with a protective curtain built over, to provide additional safety against falling workpieces.