Machine: Feeding / Dispensing

Feeding / Dispensing

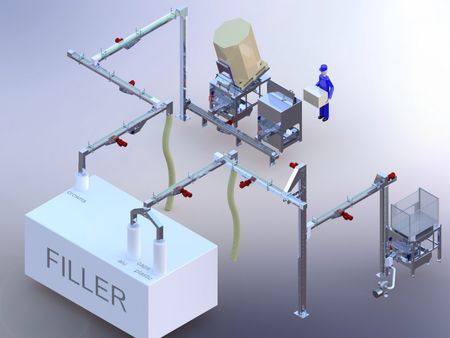

With the LID MASTER and LID SERVER, NSM offers modular systems that can be individually adapted. In combination with buffer magazines and transport systems, we can feed and distribute lids and closures to connected processes.

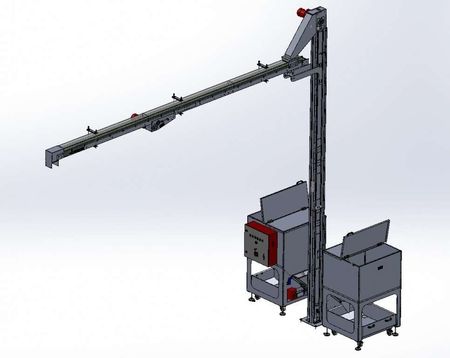

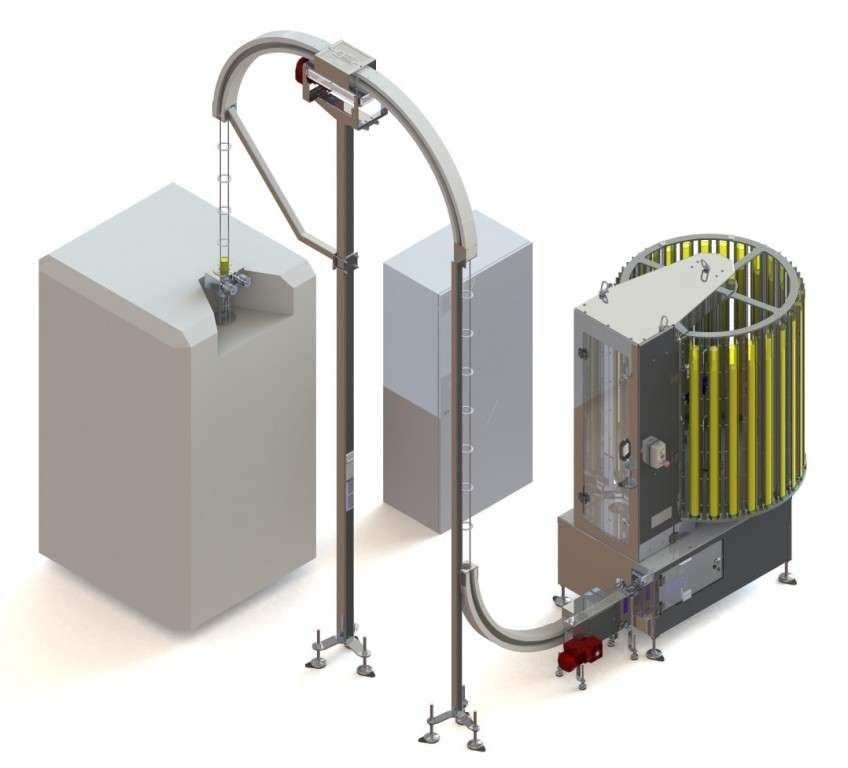

Beverage can lids and tinplate lids

The continuous and trouble-free supply of lids is essential for modern production processes.

The NSM Lid-Server and Lid-Master designed on these requirements. With low space requirements and easy handling, lids are fed automatically.

Behind the press NSM Synchronizers offer the smooth connection of several tracks into a few strands.

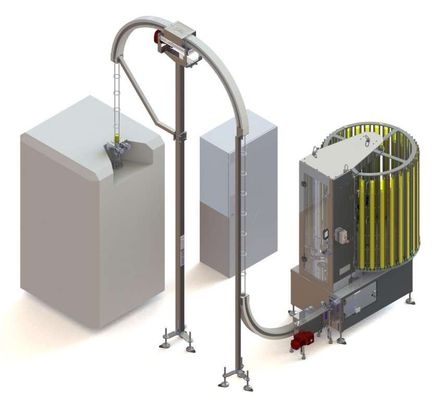

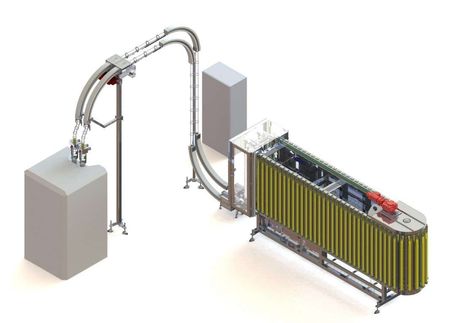

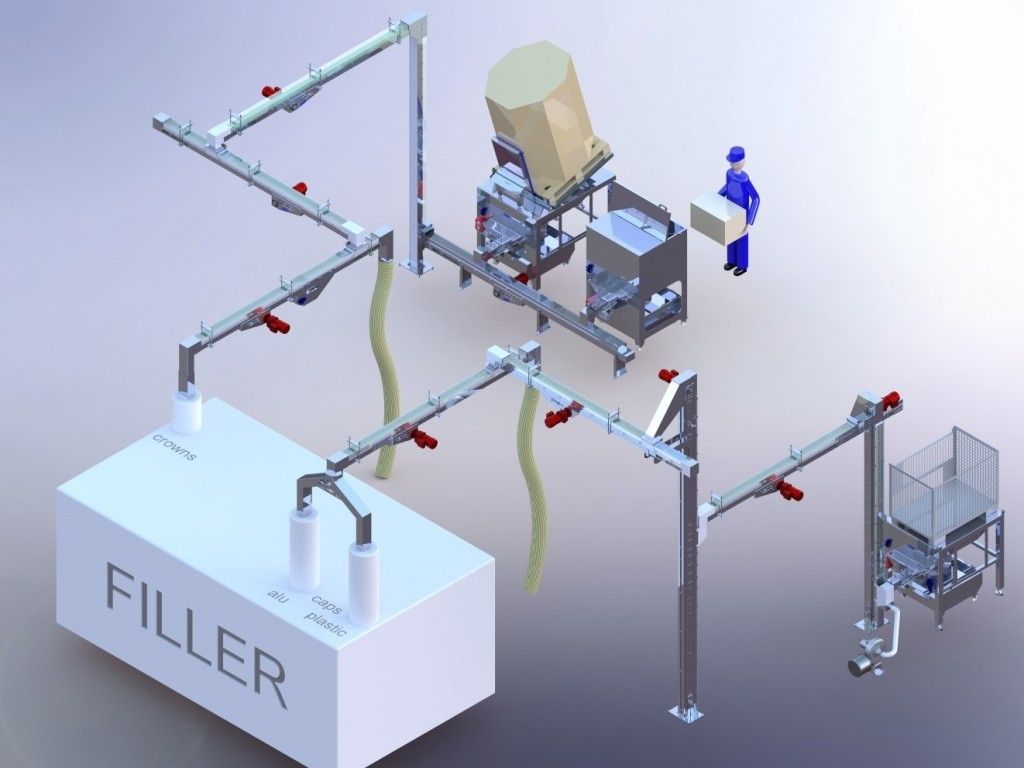

Crown corks and screw caps

In order to achieve a high degree of efficiency in modern filling lines a powerful and reliable feeding system for crown corks and screw caps is required.

The Corkmaster from NSM fulfils this task reliably, low-maintenance and cost-effectively.

Solutions for aluminium or plastic closures:

- 150.000 Crowns corks/ hour

- 90.000 screw caps / hour

Feeding in hand box, storage container, mesh box or Octabin container.

Conveyor systems of over 100 m with intelligent SPS controls.

- Better efficiency of the entire plant

- Depending on the degree of automation, operation can be reduced to one operation per shift.

- Reliable and functionally safe

- Low maintenance and robust made of stainless steel

- Cost-effective, modular design

| Typ | Eigenschaft |

|---|---|

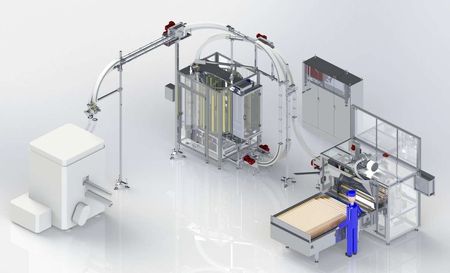

| Typ 334 manuelle Handeinlegestrecke | Bis zu 6m Einlegestrecke Einfache Schützensteuerung |

| Typ 581 Lidserver A30 | Bis zu 30 Puffertaschen Einstellbar auf verschiedene Deckelformate 1 oder 2 spurige Ausführung SPS Steuerung |

| Typ 580 Lidmaster A40, A60, A80, A96 | 40, 60, 80, 96 Puffertaschen 1 oder 2 spurige Ausführung SPS Steuerung |

-

Conveying Systems for Crown Corks

download

Here you will find our latest brochure about conveying systems for crown corks and screw caps / twist-offs.

-

End Feeding Systems for beveraged ends - Part 1

download

Here you will find our latest brochure about end feeding systems for beveraged ends type 200, 202 , 206, 209… and for tin-plate ends.

-

End Feeding Systems for beveraged ends - Part 2

download

Here you will find our latest brochure about end feeding systems for beveraged ends type 200, 202 , 206, 209… and for tin-plate ends.